Reduction in order processing time.

Decrease in production waste.

Reduction in manual communication errors.

A 150-year-old agricultural sciences company (headquartered in Philadelphia) sought to address inefficiencies in its custom chemical mixing process. They have a long history of serving American farmers by producing the machinery and chemicals used in the food industry, with crop protection being one of their largest operations. Manual communication between farmers, sales reps, and machine operators led to frequent errors, waste, and significant costs. The company had already built an impressive network of production machines and a robust retailer network to support operations. However, the “telephone game” of relaying orders from farmer to sales rep to machine operator proved costly and error-prone.

Net Solutions built a comprehensive ordering platform that automated communication between farmers, retailers, and mixing machines. By leveraging existing internet-enabled chemical mixing machines and employing SCADA (Supervisory Control and Data Acquisition) principles, specifically the Ignition Vision module, the platform eliminated human error, optimized workflows, and enabled real-time analytics for operational insights.

“Net Solutions brought the ‘A’ team to the project, adding significant value with their expertise and innovative solutions.”

01. Automated Order Fulfillment

02. Optimized Retailer-Farmer Communication

03. Data-Driven Insights for Process Improvement

The platform connected farmers’ orders directly to chemical mixing machines, reducing manual errors and improving turnaround times. It bypassed sales reps as middlemen, ensuring farmers’ requirements were accurately translated into machine parameters without delay.

Farmers received ETAs for order readiness, streamlining the pickup process and enhancing transparency. The system also gave retailers live status updates, reducing guesswork and manual follow-ups.

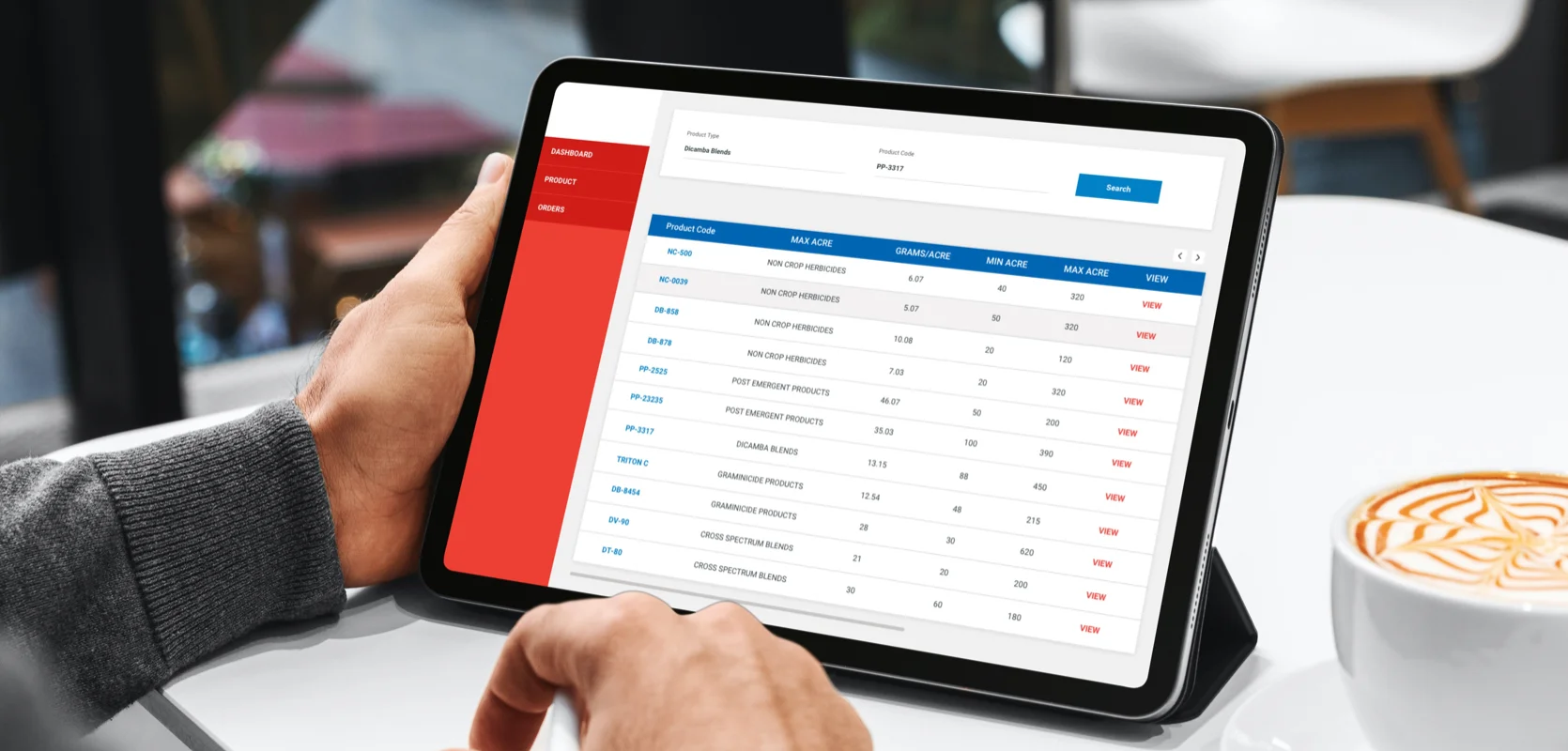

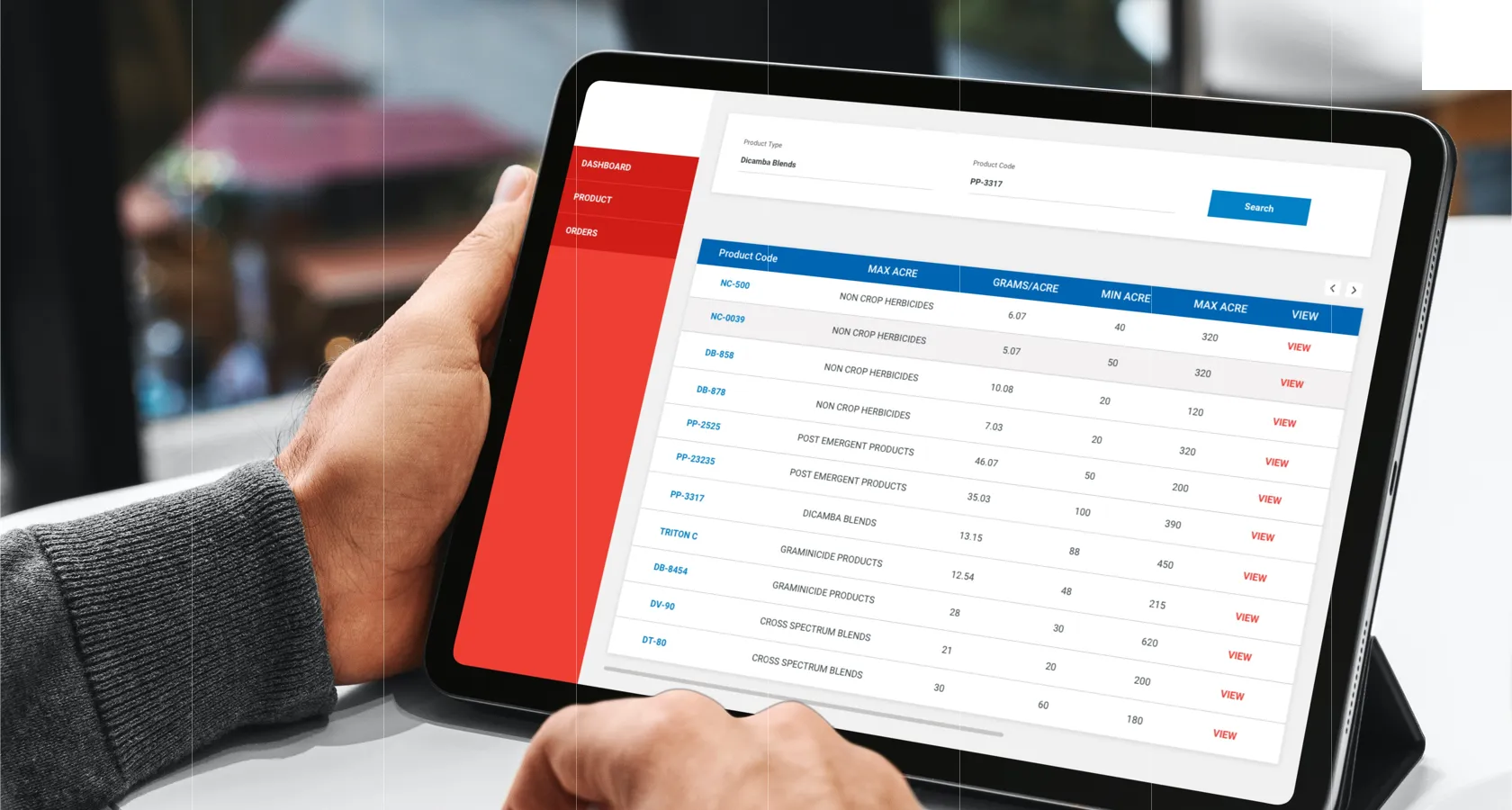

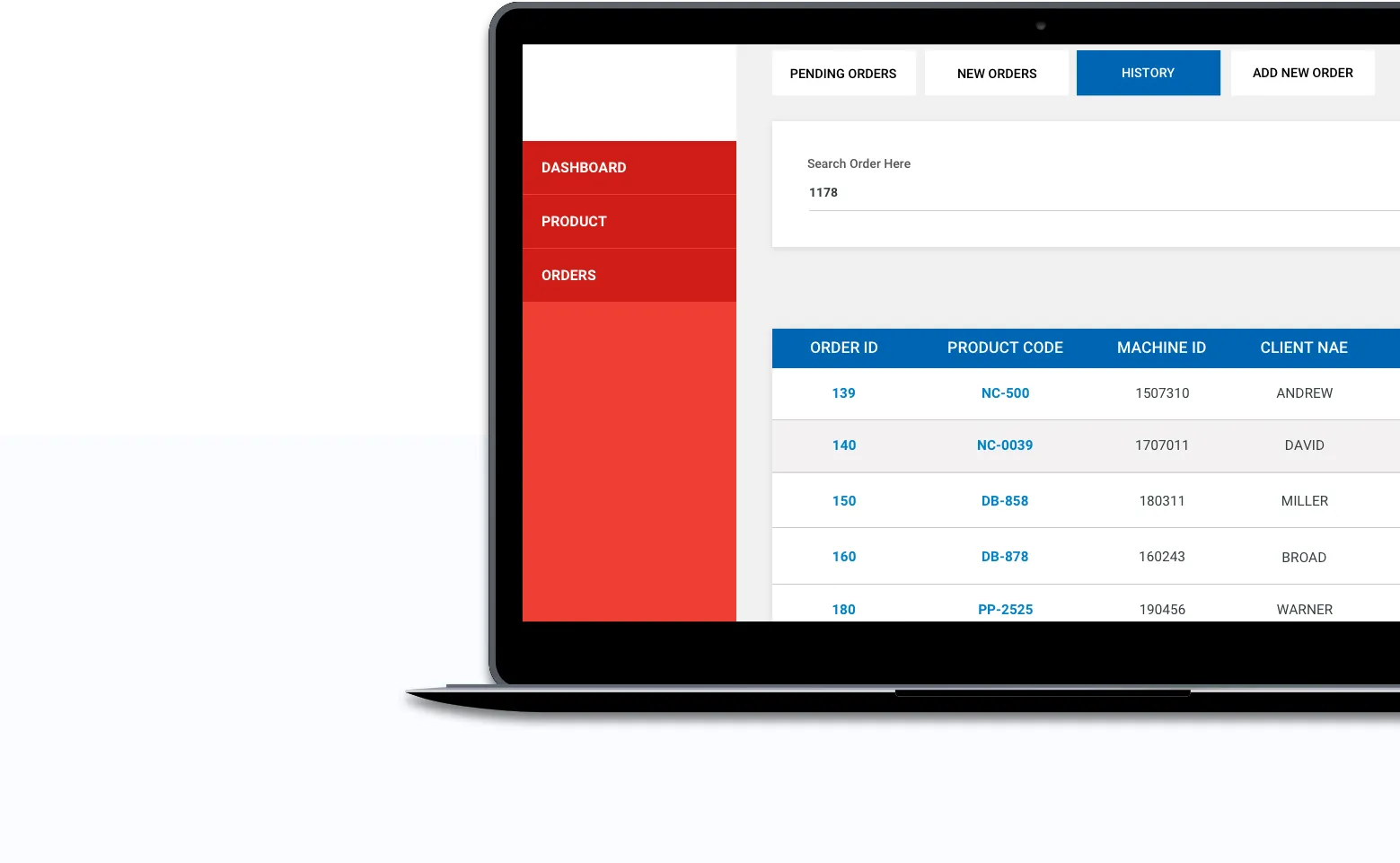

Farmers could place detailed orders via the mobile app, while retailers used a web app to verify availability and manage order pipelines. The apps were designed using Ignition Vision for a seamless experience that connects directly to the backend.

The intuitive design made it easy for farmers and retailers to navigate the platform and manage transactions efficiently. By eliminating cumbersome phone and email exchanges, communication errors dropped significantly—ultimately saving time and costs.

The backend tracked order data, providing actionable insights and enabling the company to spot trends and optimize production. Managers leveraging a MySQL database gained real-time visibility into orders, operational metrics, and emerging patterns, helping refine their processes.

Built with future growth in mind, the system supported increasing order volumes without performance issues. The technology stack, integrated with the internet-enabled machines, was designed for smooth, large-scale rollouts across additional retailer locations.